Magnetic stirrers: The "invisible housekeeper" in the lab – have you made the right choice?

Magnetic stirrers: The "invisible housekeeper" in the lab – have you made the right choice?

While seemingly just about "heating and rotating," magnetic stirrers are involved in almost every experiment requiring mixing or heating, directly impacting efficiency and results.

A well-matched magnetic stirrer is a crucial tool for standardizing experimental procedures and ensuring research reproducibility.

LABONE Instruments has been deeply involved in the field of magnetic stirrers for many years and has now formed a complete product system covering room temperature to 550°C, single-channel to multi-channel, and teaching to production scale-up.

Step 1: Clarify Three Questions Before Choosing a Model

Before selecting a specific model, it is recommended to answer the following questions:

1.Is stirring required?

2.Is heating required?

3.If heating is required, does the maximum temperature exceed 340℃?

No stirring required → Choose a "Pure Heating Plate"

Suitable for experiments involving drying, constant temperature heating, and preheating of solid samples, where liquid mixing is not involved.

In these scenarios, heating stability is more important than stirring functionality. Choosing a pure heating plate is more direct and easier to manage.

Common selection directions:

· Based on maximum heating temperature requirements

· Based on plate size and load-bearing capacity

No heating required → Select "Pure Stirring Type"

Suitable for routine solution mixing, low-temperature reactions, sample pretreatment, etc.

These types of experiments only focus on the stability and uniformity of stirring, without temperature control requirements. A pure stirring type is sufficient, offering a simpler structure and greater flexibility.

Common selection criteria:

·By tray size (4-inch / 5-inch / 6-inch / 7-inch)

·By multi-channel requirement (single-channel / multi-channel)

Heating and stirring both require → Select a "Heated Magnetic Stirrer"

In LABONE's magnetic stirrer system, temperature is the most direct and crucial dividing line:

• ≤120℃ / 220℃, Suitable for routine dissolution, mild reactions, and sample pretreatment.

• 280℃ / 340℃, Covering most organic synthesis, condition screening, and teaching experiments.

• 380℃ / 500℃ / 550℃,For high-temperature reactions, mineral digestion, and strong acid systems.

Step 2: Prioritize Application-Specific Features

R&D, Pharma & Chemical Labs

Precision, safety, and reproducibility are critical. Required features include precise temperature and speed control, chemical resistance, timers, alarms, and power-off memory to ensure process integrity and data reliability.

University Teaching Labs.

Safety and ease of operation are paramount for foundational experiments like distillation and recrystallization.

Recommended models: MS-H280-F100 / MS-H380-F100

Why: Enclosed heating design prevents burns; brushless motors eliminate spark risks; simple interfaces suitable for teaching environments.

Reasons for recommendation:

High heating efficiency, quickly reaching the set temperature, significantly reducing experiment time and improving teaching efficiency;

A more secure connection between the heating mantle and the reaction flask, with no exposed surfaces, avoiding the risk of burns;

Internal dual-circuit safety design, brushless motor with no sparks, making prolonged heating in chemistry labs safer;

The MS-H280-F100 split-type magnetic heating mantle is dual-purpose, allowing simultaneous heating and stirring experiments;

The metal shell with an anti-corrosion powder coating is corrosion-resistant and easy to clean.

✓ Digestion and Metal Content Determination of Metal Mineral Samples:

Many heavy metal minerals in nature, such as Cd, Pb, and Mn, exist as insoluble silicates or sulfides. These require digestion using a mixed acid solution of hydrofluoric acid (HF) and nitric acid (HNO₃). Under heating and stirring conditions, the decomposition of insoluble minerals is accelerated, yielding soluble metal salts for subsequent metal content determination and purification.

Recommended magnetic models: DMS7-550M, DMS4-550, MS10-H500-Pro, MS7-H550-Pro

Reasons for recommendation:

Dual independent safety circuit design continuously monitors the equipment, cutting off power in case of overheating or abnormal operation, ensuring safety and reliability;

Ceramic disc surface, highly resistant to strong acid solutions, stable and durable;

Maximum temperature >500℃, high thermal output power, rapidly heating and dissolving minerals;

High-efficiency flow guiding platform quickly guides splashed liquids to the outside of the instrument, preventing corrosion of internal components;

Brushless motor provides powerful stirring, preventing mineral particle deposition, promoting full contact between acid and sample, and accelerating experiments.

✓ Drug Synthesis Route and Condition Screening and Optimization:

For example, in the three-component condensation reaction of the antimalarial drug chloroquine intermediate, the feed ratio of 7-chloro-4-hydroxyquinoline, 1-diethylamino-4-aminopentane, and the condensing agent formaldehyde, as well as the reaction temperature, time, and pH value, directly affect the product yield. The reaction temperature is particularly important; too low a temperature leads to incomplete reaction, while too high a temperature results in byproducts that are difficult to purify the main product. In the small-scale test stage, it is necessary to control each variable to screen for the optimal conditions.

Recommended magnetic fluxes: DMS5-340, MS-H-ProA, MS-H340-S4, MS-H280-S6

Reasons for recommendation:

Brushless DC motor, spark-free operation, safe and reliable for extended periods;

Adjustable heating modes (A, B, C), with mode C suitable for small-volume, multi-sample screening experiments, ensuring uniform heating and no overshoot;

Parallel magnetic field magnet, providing uniform magnetic field strength across the disk, ideal for simultaneous stirring of small-volume, multi-sample experiments with excellent uniformity;

4/6 channels with independent temperature and speed control, ensuring good experimental repeatability and reliable data;

Compatible with various reaction modules and containers, enabling simultaneous screening under multiple different conditions, resulting in high experimental efficiency.

Food Processing and Analysis

Prioritizing Economy: As auxiliary equipment in sample pretreatment or heating processes, stability, durability, ease of operation, and cost-effectiveness are paramount.

✓ Detection of Organophosphorus/Organochlorine Pesticide Residues on Vegetable Leaves:

In food safety testing, the determination of pesticide residues and other harmful substances requires extremely high uniformity, efficiency, and reproducibility in sample pretreatment.

For example, in the pretreatment process for determining organochlorine pesticide residues on spinach leaves, the spinach leaf sample needs to be chopped, mixed with acetonitrile, and then the QuEChERS salt packet added. The mixture is stirred at 40-50℃ and 300-400 rpm for 30 minutes to fully extract the organochlorine from the leaves. After standing, the supernatant is used for GC-MS and LC-MS analysis of the residue levels.

Recommended Magnets: DMS5-280, MS-H280-Pro, MS-H-S10

Reasons for recommendation:

Economical and suitable for large-scale sample pretreatment for testing and analysis;

The MS-H-S10 can process 10 samples simultaneously, allowing for multiple parallel experimental controls and more reliable results;

Simple operation with quick setting of experimental temperature and speed;

Long-lasting brushless motor with stable operation, capable of long-term use.

Bioengineering

Low shear force, low heat generation, stable rotation speed, and programmed operation function.

Suitable for cell culture, bio-enzyme, antibody, vaccine, and other production and preparation processes.

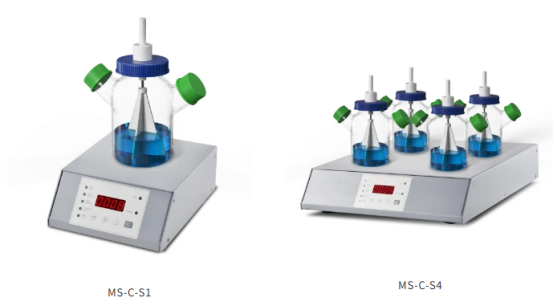

Recommended products: MS-C-S1, MS-C-S4

Reasons for recommendation:

Compact design, suitable for use in incubators;

Selectable constant speed mode, intermittent start mode, and dual-speed mode as needed;

Smooth and gradual acceleration and deceleration effectively avoids cell damage caused by excessive agitation during start-up or shutdown;

Low speed protects cells from damage.

After reading this article, do you realize that choosing a magnetic stirrer isn't actually that complicated?

Just think clearly about three things: "whether it stirs," "whether it heats," and "temperature range," and you'll be able to choose your ideal magnetic stirrer!