Cosmetics Texture Measurtement System Device Food Physical Property Analyzer Food China LBW-10HS Texture Analyzer Texture Tester

LBW-10HSTexture AnalyzerProduct Advantages1.1 A touch-sensitive keyboard serves as an auxiliary keypad, faci

LBW-10HS Texture Analyzer

Product Advantages

1.1 A touch-sensitive keyboard serves as an auxiliary keypad, facilitating testing and enabling offline device control.

1.2 Quickly and safely replace the force sensor element. By switching between force sensors, the test range and resolution accuracy (0.001g to 0.0001g) can be adjusted to accommodate different sample analyses.

*1.3 Video and image capture capabilities allow for full recording of critical sample tests, which are then displayed synchronously with other test data and strain curves in the software window and saved to a traceable database.

1.4 A data acquisition rate of 4000 sets per second captures the precise moment of sample change, eliminating missed or false positives.

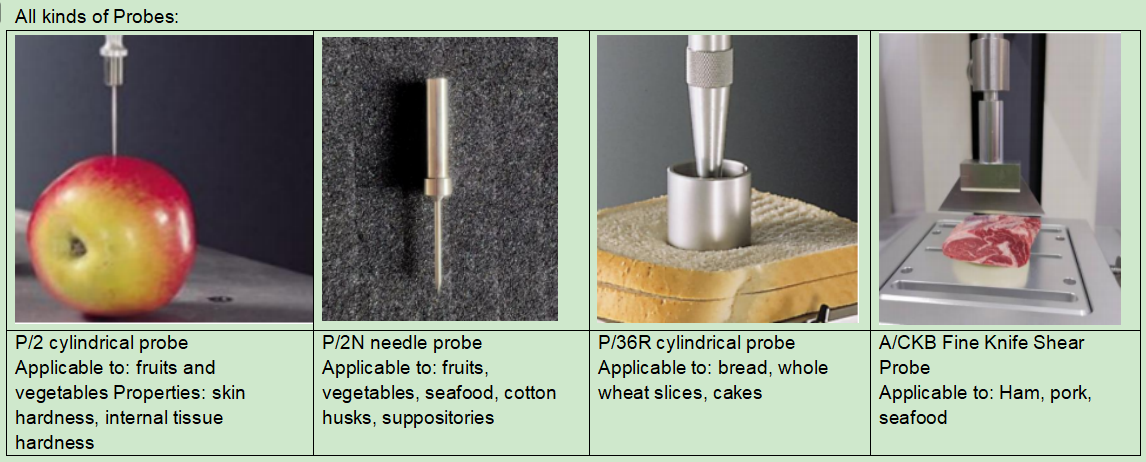

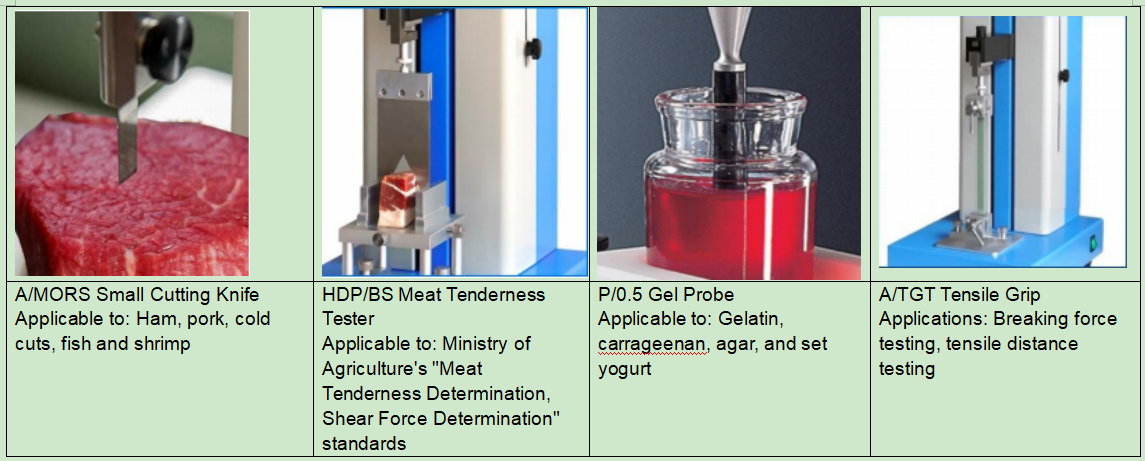

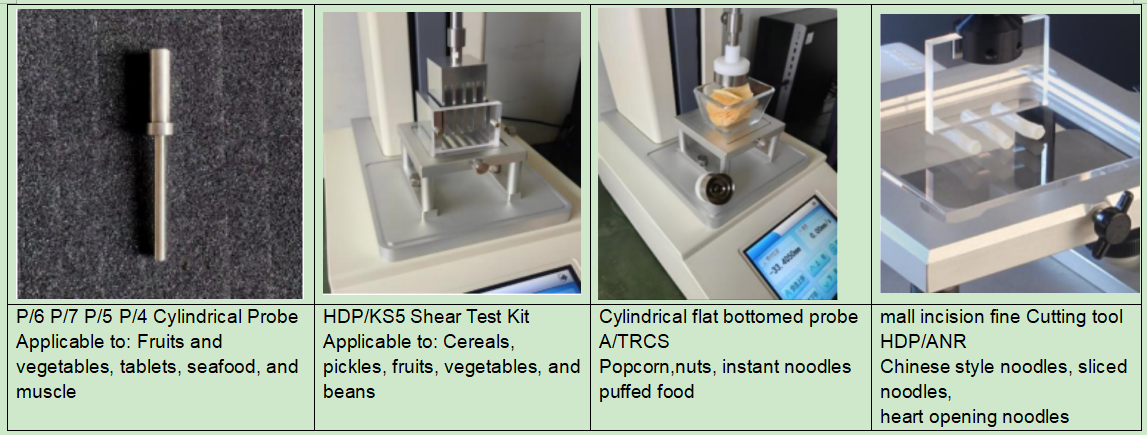

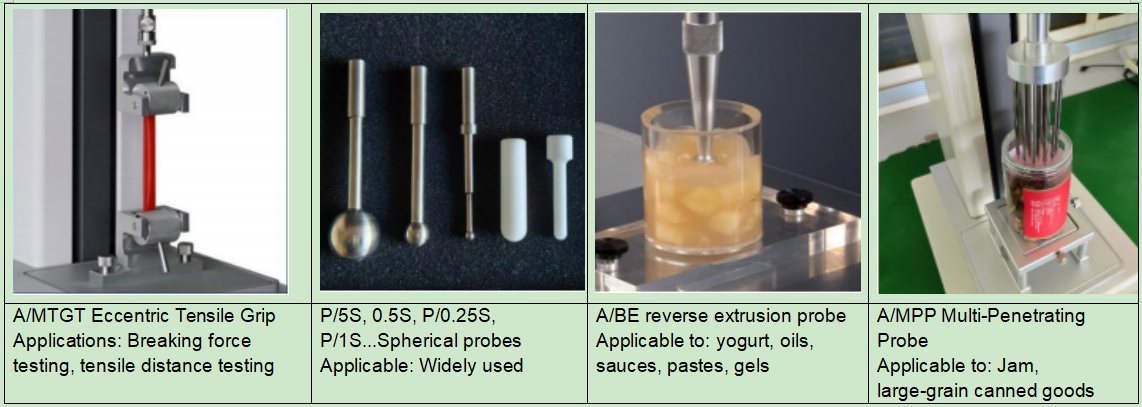

Applications: The LBW-10HS is suitable for analyzing the physical properties of samples such as gelatin, carrageenan, curdlan, frozen surimi gel, agar-agar composite hydrogel, sodium hyaluronate gel, pharmaceuticals (tablets, capsules, ointments, patches, suppositories, aspirin-forming formulations, and powders), tobacco, cosmetics, dairy products, meat products, aquatic products, grain and oil products, rice products, flour products, traditional Chinese medicine, tobacco, fruits and vegetables, baked goods, jellies, candies, and jams. It can accurately quantify a variety of physical properties, including gel strength, hardness, brittleness, tenderness, viscosity, elasticity, toughness, cohesion, chewability, yield strength, tensile strength, burst strength, shear strength, compressive strength, penetration strength, composite modulus, elastic modulus, creep properties, and relaxation properties.

Key Technical Parameters and Features

3.1 Force Sensor Size: 25 kg (0.5, 1, 2, 5, 10, 20, 25, 30, 50, and 100 kg optional)

23.2 Force Sensor Accuracy: ≤0.01% FS

3.3 Force Resolution Accuracy: 0.001 g to 0.0001 g (real-time, simultaneous display)

3.4 The instrument features multiple protections: emergency braking, upper and lower limit controls, force sensor overload protection (customizable overload warning settings), and test data encryption.

3.5 Measuring Arm Range: 0-310mm, 0-410mm optional

*3.6 Displacement Resolution Accuracy: 0.0001mm (Real-time, Synchronous Display)

*3.7 Detection Rate: 0.001-45mm/s-60mm/s (Optional)

*3.8 Detection Rate Error: ≤0.1%

*3.9 Data Collection Rate: Up to 4000 sets/second, Selectable: 20, 50, 100, 200, 500, 1000, 2000, 4000, Custom (Customized collection rate settings are suitable for universities and research institutes to export specialized data).

*3.10 Force Accuracy Verification and Automatic Calibration: The instrument provides a precision measurement and verification interface. Through continuous testing of five standard samples, acceptable or out-of-tolerance test data is determined and displayed directly on the software. The instrument automatically performs measurement and calibration using a data algorithm, prints a measurement report, and stores the data in an audit database.

*3.11 Deformation Displacement Accuracy Verification and Measurement with Automatic Calibration: The instrument comes standard with a displacement accuracy measurement interface, which communicates with the software via an electronic micrometer. Acceptable or out-of-tolerance test data is displayed directly on the software. The instrument automatically completes measurement and calibration using a data algorithm, prints a measurement report, and stores the data in an audit database.

3.12 Test Methods: (Over 20 test methods available)

Single compression, cyclic testing, compression hold testing, relaxation properties testing, creep properties testing, full texture testing, tensile testing, compression testing, bending testing, shear testing, puncture testing, meat tenderness testing, gel strength testing, carrageenan-surimi gel-curdlan-agar strength-hydrophilic gel testing, noodle product testing, rice product testing, seafood testing, adhesion testing, compression modulus, elastic modulus testing, and more. The software also supports quick custom test mode addition.

IV. System Software Overview

4.1 Comprehensive test mode program editing functions include run, preset, repeat, loop, clear, zero calibration, assignment, variables, formulas, calculations, playback, comparison, and annotation. By editing these program commands, you can implement various test modes, build various test models, and obtain the required test data.

*4.2 Test Playback: The software automatically records the entire test process (including simultaneous recording) and provides multi-method intelligent retrieval. Tests from any period can be traced back to perform data restoration, curve redrawing, and simultaneous recording playback to view and analyze test details of the queried sample.

*4.3 The software can simultaneously select up to 15 current or historical test results (function curves, measurement data, and simultaneous recordings) for comparative analysis. The software can overlay multiple texture curves in different colors, making it easy to compare and analyze the results of multiple tests.

4.4 Data Analysis: The software can display four function curves: force-time, force-distance, distance-time, and stress-strain. The graph includes a scale, allowing for arbitrary zooming of parts of the graph or automatic system adjustments. Key data points are automatically labeled. During data analysis, any area of the selected graph, any desired data point parameters, and automatically calculated results (including curves, overlays, images, and data) can be automatically generated and exported to Excel/Word/PDF files.

4.5 The LBW-10HS system software provides in-depth solutions and descriptions for each test. In addition to standard test modes, it also offers user-defined and customizable program editing and practice. Custom reports and test plots can be easily created. Test data can be directly exported to various formats, including Excel/Word/PDF, for data export, graphing, saving, comparison, and professional report generation.

4.6 The software supports test modes: timed, position-shift, fixed load, single cycle, multi-cycle, compression, tension, puncture, shear, bending, extrusion, bonding, tearing, hold, intermittent, rupture, fracture, relaxation, creep, and custom modeling.

4.7 The software features a user-friendly interface: the menu bar, toolbar, status bar, display bar, curve frame, video frame, and experimental process are all clearly visible, with convenient and quick control buttons.

4.8 The software offers both Chinese and English operating systems, with one-click switching.

4.9 The software offers powerful technical support: users can find any tips, routines, analysis methods, methods, or links they need in the "Help" drop-down menu. It provides classic case methods for 24 major test categories and 20 practical instructional videos to help you quickly become an expert in physical property analysis.

*4.10 The software has a copyright certificate approved by the National Copyright Administration of the People's Republic of China. The full name of the software is "Texture Analyzer Operation and Analysis Software." This software provides functions for operating, controlling, and analyzing texture analyzers. The software's data analysis algorithms include, but are not limited to, principal component analysis, linear discriminant analysis, and partial least squares regression. This allows for quantitative evaluation of human sensory and instrumental data to determine sample mechanical properties, helping experimenters accurately determine sample shelf life, freshness, texture quality, fermentation time, and chewing characteristics.

V. Applicable Standards:

◆ "Chinese Pharmacopoeia" 2025 Edition.

◆ Complies with current Chinese Good Manufacturing Practice (GMP) regulations.

◆ National Standard "Food Additive Gelatin" GB6783-2013.

◆ National Standard "Medicinal Gelatin Hard Capsules" GB13731.

◆ National Standard "Food Additive Gelatin - Curdlan" GB28304-2012

◆ National Standard "Frozen Surimi" GB/T36187-2018

◆ Light Industry Standard "Edible Gelatin" QB/T4087-2010

◆ Agricultural Standard "Determination of Meat Tenderness - Shear Force Method" NY/T1180-2006

◆ AACC 74-09 Bread Hardness Test (American Association of Cereal Chemists)

◆ AOAC (American and European Gelatin Association)

◆ AACC 16-50 Noodle Hardness Test Method (American Association of Cereal Chemists)

◆ ASTM 1981 D882-80a Thin Film Test (American Society for Testing and Materials)

◆ BS (British National Standard)

Send Request

You may also like